3d-A fastener is a part used to join, secure, or clamp two or more parts. Common fasteners mainly include the following:

Bolt: A rod-shaped fastener with a thread that is used in conjunction with a nut. A bolt usually consists of a head, a rod and a thread.

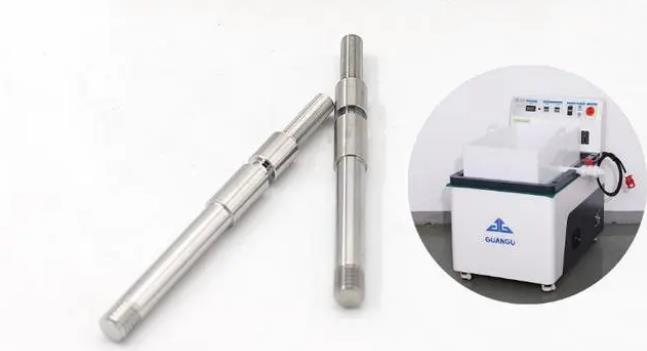

Magnetic polishing effect of fasteners

Nut: A hexagonal part with internal threads that is used in conjunction with a bolt to secure two or more parts.

Washer: A part, usually round, used to disperse force and prevent fasteners from loosening or damaging the fastened part.

Stud: A rod-shaped fastener similar to a bolt, but without threads, that is used in conjunction with a nut.

Lock nut: A special nut that prevents fasteners from loosening, usually with an anti-lock structure or a lock piece.

Bolt pin: A pin that acts as a lock between a fastener and a nut.

Rivet: A cylindrical fastener used to join two or more plates, usually operated with specialized rivet pliers.

Screw: A part that directly secures a secured part to another part, usually operated with a tool such as an electric screwdriver.

Bolt stud polishing effect

Can fasteners be polished with a magnetic polisher

Generally speaking, fasteners that do not contain magnetism can be polished with a magnetic polishing machine. Magnetic polisher is a device that polishes a steel needle by magnetic force and spins it. It is commonly used for polishing, polishing and chamfering the surfaces of small and medium workpieces. In the polishing process, the magnetic polishing machine will mix the abrasive and polishing liquid together and spray it on the surface of the workpiece for polishing.

For small workpieces such as fasteners, special clamps can be used to attach them to the magnetic polishing machine to ensure that they can safely rotate and receive polishing. Before using a magnetic polisher to polish, it is necessary to select the appropriate polishing fluid, abrasive and polishing time to achieve the desired polishing effect.

The fasteners are polished with a magnetic polisher

It should be noted that different types of fastener materials have different hardness and corrosion resistance, so when using magnetic polishing machine for polishing, it is necessary to choose the appropriate polishing fluid and abrasive according to the material and requirements of the fastener, to ensure that there will be no damage to its surface.

Wechat

Wechat